Camshafts

OVERVIEW

Camshafts is one of the most important components which precisely operates the Rocker arm and Tappet valve movement to timely manage all the 04 strokes required for combustion of Engine.

It’s a Casting part which is machined in very tight precision tolerances here in India and exported to Spain.

Paper Tube with VCI & Bubble bag is traditionally used combination for final dispatch packaging of camshafts in Master Corrugated box.

CHALLENGE

Convincing the camshaft manufacturer Sourcing team that traditional Paper tube packaging method has some limitations and we can improvise the complete supply chain was the basic challenge.

Once the opportunity was given to participate and present a proposal for improvement by customers’ management team; we understood the existing supply chain process in detail from In-ward stores to Container stuffing and End customer line Feeding.

We identified and Surfaced the below-mentioned Problems which were ignored or pushed away in day to day activity:

- Empty Paper tube Store space consumption was the same as filled.

- Labour fatigue in packaging with more time consumption.

- Room to increase packaging density/box.

- 70% container capacity utilized.

- Box Wall swelling during transit.

- Paper Tube disposal issues major at Spain.

- Repackaging needed at Spain warehouse in customer trolleys.

SOLUTION

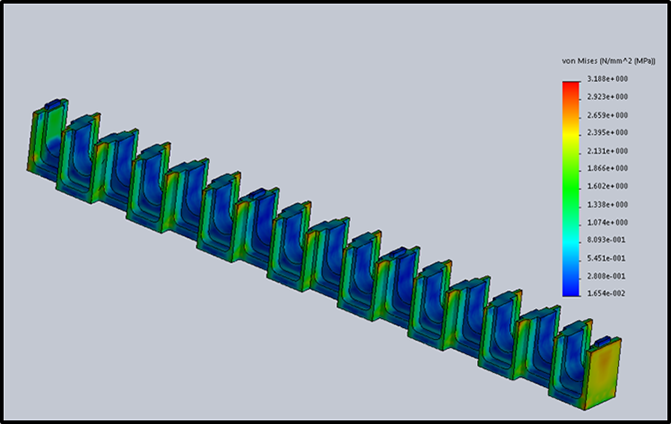

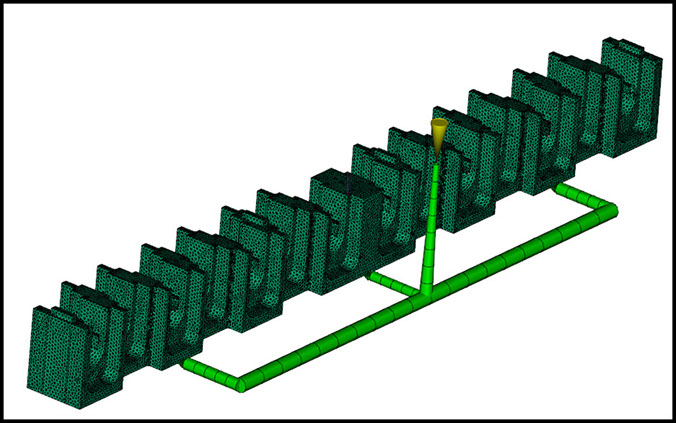

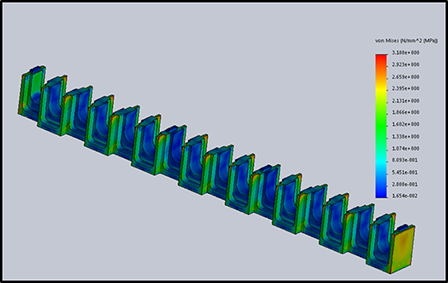

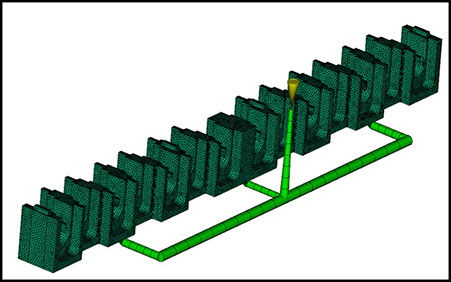

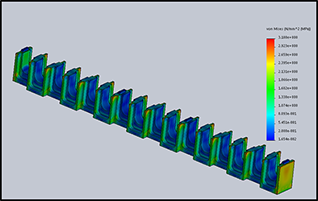

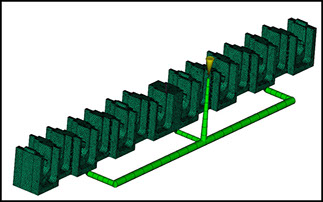

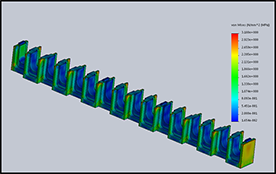

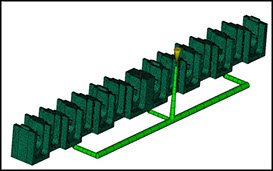

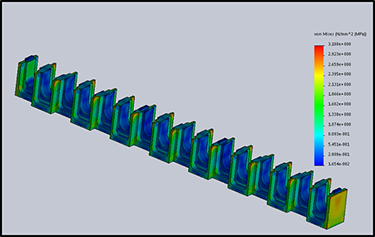

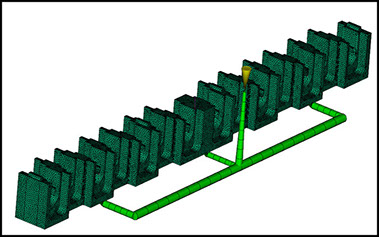

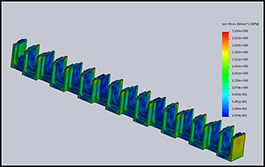

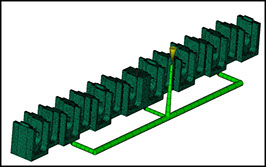

Plastic Buffer for safe camshaft packaging & direct Engine assembly line feeding for the end customer.

.jpg?crc=256813625)

RESULT

- Product safety - Positive locking, Orientation & optimized Gap for each camshaft during transit to ensure complete product safety.

- Simple & Ergonomic - Simple & Fatigue less Plastic buffer design to improve > 50% labor efficiency while packaging & unpacking.

- Efficiency - 35% more camshafts in the same box as compared to Paper tube.

- Store & Container Space - About 40% warehouse space saving and 100% utilization of container capacity.

- Environment - Minimized waste disposal to Environment by eliminating paper tube and using a recyclable Plastic buffer at Spain Warehouse.

- Direct Line Feeding - No Repackaging at Warehouse needed as the Box with Plastic Buffer can now be directly sent to Engine assembly line.

- Savings – Almost INR 34 lakhs saved in 1 year from Implementation in monetary terms with value additions in the complete supply chain.

- Our earnings – Customer got convinced and changed his mindset from paper tube to Plastic buffer.

464x315.jpg?crc=4081198153)

338x229.jpg?crc=149635332)

284x192.jpg?crc=4058610115)

398x270.jpg?crc=4256204727)

266x181.jpg?crc=3882084732)

266x180.jpg?crc=302480601)