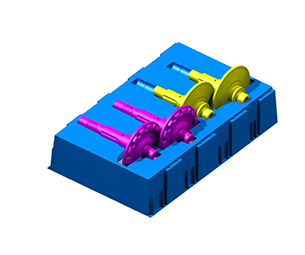

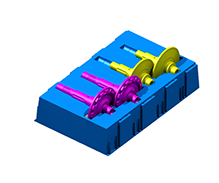

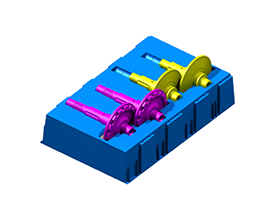

Transmission Shafts & Sheaves

OVERVIEW

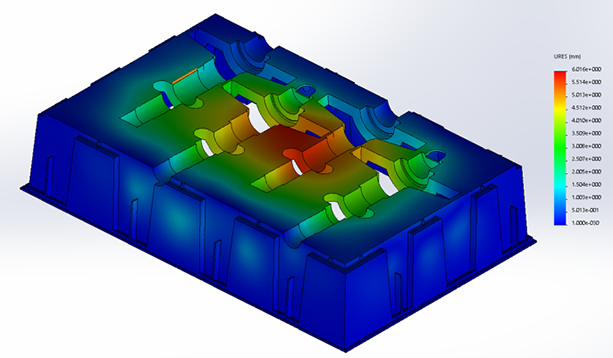

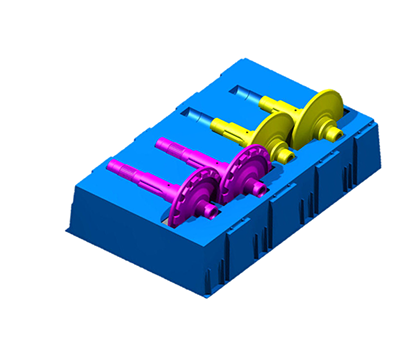

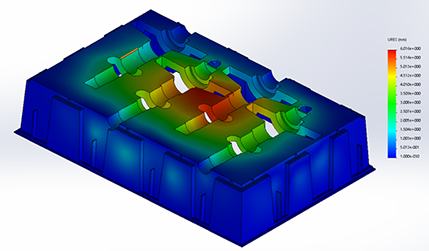

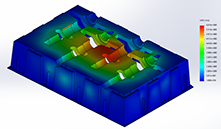

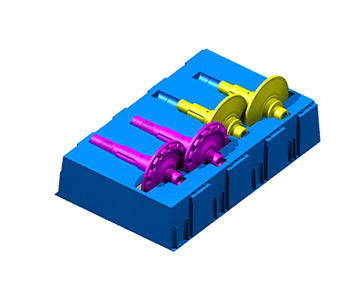

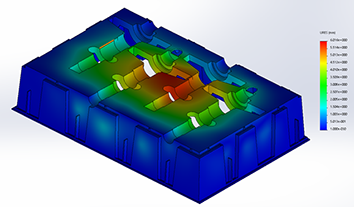

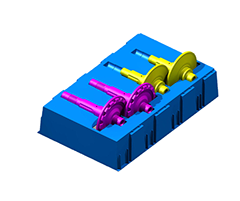

Transmission SHAFTS & SHEAVES are important mechanical components in a Drivetrain or Gear Box. These are Forged parts which are machined in very tight precision tolerances here in India for a European customer.

It’s a standard practice in Metal machining Industries to use mostly Metal Fabricated Trolleys or Wooden Boxes with Plywood separators to handled components during stage-wise machining process viz. forging – Pre turning – Heat treatment – Gear Hobbing - Grinding – Final dispatch packaging.

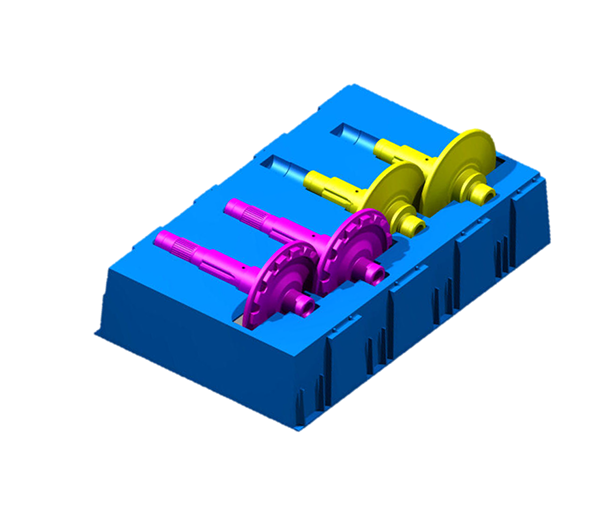

Every 06 different types of Forged Transmission SHAFTS & SHEAVES were to be handled safely between 03 different Interplant locations.

CHALLENGE

Customer had already developed around 100 no’s of Metal Square pipe Fabricated Trolleys for 05 variants for handling Pilot lot volumes.

- Dent & Damages due to metal to metal contact.

- In-efficient & Robust trolley design.

- Inventory management issues due to multiple Trolley variants.

- Labor Fatigue high.

- More Warehouse & Truck space needed.

These were the problems faced by the customer which were to be solved within 45 days before the production ramp up.

SOLUTION

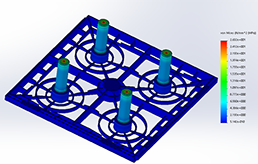

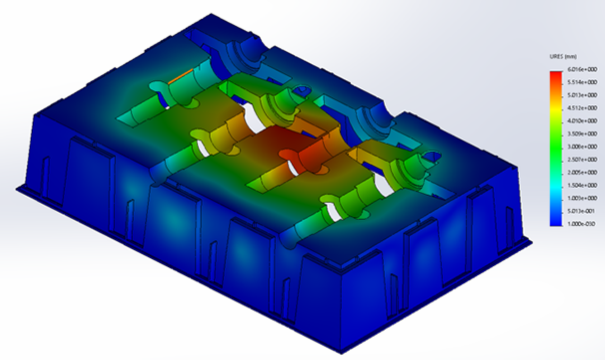

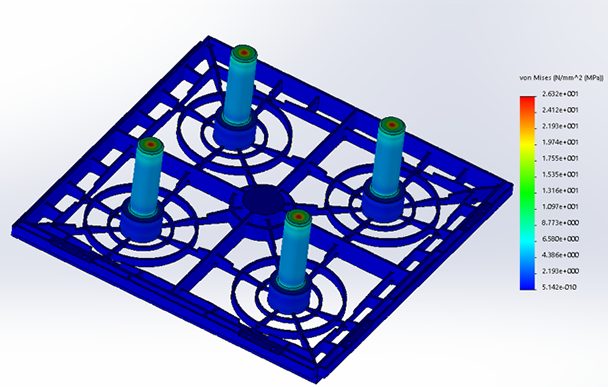

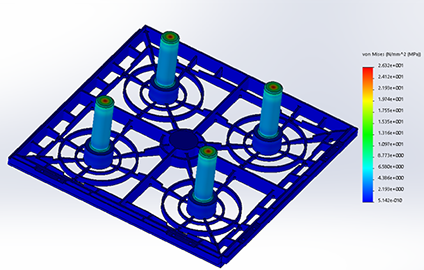

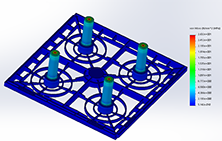

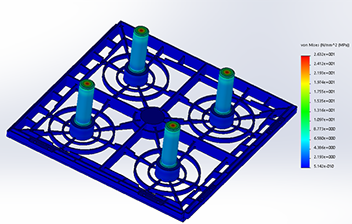

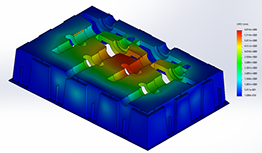

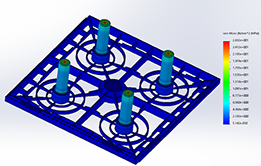

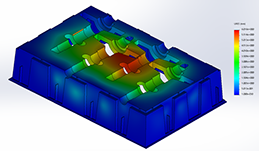

We Developed 02 variants each of Durable Lightweight plastic crate for all 06 shafts & 06 sheaves respectively.

.png?crc=4174389465)

RESULT

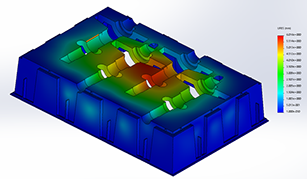

- Product safety - Positive locking, Orientation & optimized Gap for each shaft during handling and transit to ensure complete product safety.

- Simple & Ergonomic - Lightweight crates and Visually identified locations for shafts & sheaves made the Loading & Unloading very easy and fatigueless for Labor.

- Inventory Management - Only 02 variants of Plastic crate made the life easy for the Material Store manager and PPC team.

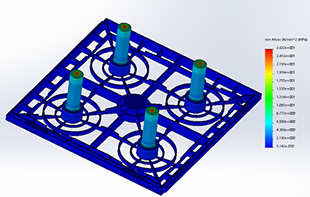

- Efficiency - Shafts 40% & Sheaves 80% efficiency increased by a Compact design of Crates compared to Trolley.

- Warehouse & Truck Space - Efficient Loaded pallet with shafts and Nest-able Empty plastic crates saved almost > 50% handling floor space.

- Washable – Ease in washing with cutouts in a crate for water draining prevents it from accumulating Oil, Dust and Burr.

- Maintenance - Quick, Easy and low cost; just replace one single damaged crate with a new one instead of holding the complete trolley for maintenance.

- Savings – Almost INR 150 lakhs in 04 months from the date of Implementation in monetary terms, while at the same remarkable improvements in overall material handling process.

- Our earnings – Of course, we won the business; but the Smile on the end users face and Appreciation from customer team were our earnings to keep motivated.

432x274.png?crc=298951415)

309x197.png?crc=195592326)

223x141.png?crc=4239890977)

363x230.png?crc=4149946072)

262x167.png?crc=3875013775)

264x168.png?crc=3858822716)